EDDY CURRENT SEPARATORS

STAR TRACE Eddy Current Separators devices are an effective way of removing non-ferrous metals from other products. Application such as aluminum cans from municipal waste, aluminum flakes from shredded PET, brass and aluminum from foundry sands, and metals from shredded automobile scrap, other metals such as lead can also be removed. For successful non-ferrous separation, a magnet should be installed prior to an Eddy Current Separator.

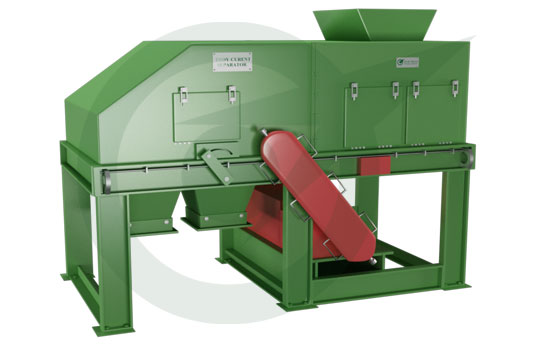

STAR TRACE Eddy Current Separators are ready to be installed for separation. This separator utilizes a powerful Eddy Current Rotor, Conveyor Belt, two variable discharge area and support frame. The optional vibratory feeder provides a consistent flow of material to the Eddy Current Separator. The main principle is that 'an electrical charge is induced into a conductor by changes in magnetic flux cutting through it'. Moving permanent magnets passing a conductor generates the change in magnetic flux.

STAR TRACE Eddy Current Rotor uses an alternating magnetic field to produce electrical currents in conductive metal. The electrical current generates its own magnetic field around an object which opposes the magnetic field from the Eddy Current. This repulsion diverts the object from the product stream. Mass, conductivity and density influence the force and distance an object will repel.

Eddy current separators are based on the use of a magnetic rotor with alternating polarity, spinning rapidly inside a non-metallic drum driven by a conveyor belt. As non-ferrous metals pass over the drum, the alternating magnetic field creates eddy currents in the non-ferrous metal particles repelling the material away from the conveyor.

STAR TRACE Eddy Current Separation System encompasses all the equipment above necessary to separate non-ferrous metals and adds ferrous metal separation equipment. It is important to remove ferrous metal prior to exposure to the Eddy Current Separators. Ferrous metal is attracted and held by the strong magnetic force. The ferrous metal will heat up and could burn holes in belt and cause significant damage to the Eddy Current Rotor.

- Foundry Industries.

- Glass Industries.

- Timber Industries.

- Plastic Industries.

- Boiler Industries.

- E-Waste Industries.

- Aluminum Industries

Eddy Current Separators For Sale Benefits

The following are the benefits of Eddy Current Separators For Sale:

- Rich experience in design and production can ensure mature product technology, stable performance and reliable quality.

- Mass production, mature technology, stable quality.

- Simple structure, easy and convenient to install, operate and maintain.

- Complete secure facilities, full functions.

- Beautiful appearance, retainer plates and door panels are stainless steel wiredrawing board, high-grade lock.

Eddy Current Separators Sale Applications

- Electronic waste disposal (refrigerator dismantling line).

- Separation of aluminium cans and ferrous metals.

- Separate non-ferrous metals from the bottom ash of boiler.

- Separate aluminium or copper block from the sections of abandoned cars.

- Separate non-ferrous metals from the glass scrap,recycled plastic doors,windows and the wood

- Separate non-ferrous metal impurities in some production lines(such as plastic recycling production line).

Welcome

Star Trace Solutions Pvt. Ltd. is a prominent manufacturers and supplier of Eddy Current Separation machine, Aluminium separation, Non ferrous separators, Plastic separators used in various industrial applications.

We are manufacturers, suppliers and exporters a wide galore of Separation equipments such as Aluminium Can Sorter, Non ferrous separator, Plastic Remover and so on. We are Specialized manufacturers in fabrication of this equipment for 25 years and this enables us to be a leader in this field. we are manufacturers, suppliers and exporters having an iso 9001 2008 company and listed in D & B for confidence.

Eddy Current Separator Sale

STAR TRACE Eddy Current Separators devices are an effective way of removing non-ferrous metals from other products. Application such as aluminum cans from municipal waste, aluminum flakes from shredded PET, brass and aluminum from foundry sands, and metals from shredded automobile scrap etc. This series of products are widely applied for cement Separation, power, ore Separation, ceramic Separation, non-metallic ore Separation, metal Separation, chemical, glass Separation, paper-making, building, sugar refining, pharmaceutics, food and so on.